Beyond the basics has always been the guiding principle of FlightSafetyInternational’s maintenance technician training. It’s the difference between providing“good enough” training and allowing technicians to be the best of the best.

Now the aviation training leader has expanded its offerings, reimaginingwhat hands-on training can really mean. Working with Pratt & Whitney Canada(P&WC), FlightSafety has taken a page from computer games and the virtualworld. It has developed an innovative training technology to view an engine,interactively, and explore it down to the component level.

This cutting-edge technology improves efficiency, allows for practicalinstruction for all technicians, in an immersive, thorough trainingenvironment. Students benefit in ways beyond what traditional instruction candeliver.

Working With Pratt & Whitney Canada

For more than a decade FlightSafety International (FSI) has been apartner with P&WC, supporting P&WC Engine training programs anddeveloping curriculum for technicians at FlightSafety Learning Centers. Thisdeep relationship and collaboration perfect simulation of real-world operatorscenarios, enhancing the training experience while ensuring currency within-production build specs. As engines evolve, so do the Virtual Engine Trainermodels.

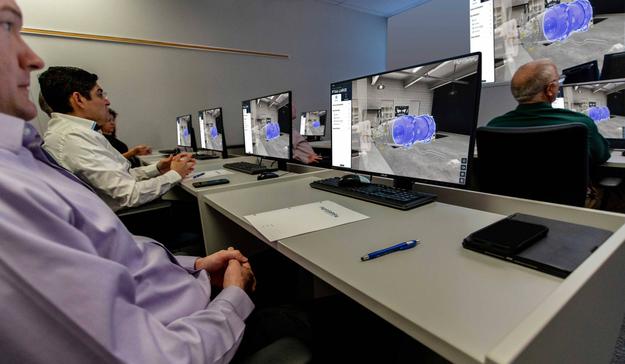

The development team took cues from advanced, computer-based technology– similar to what someone might experience with next-generation virtual oraugmented reality. In the same way that video game players have been able tomanipulate items within the game on multiple axes, the Virtual Engine Trainer (VET)allows instructors and students to view the engine and the many individual componentsin any position or system grouping, in 3D and complete clarity.

A Better Training Experience

Physical engines are heavy with difficult-to-move components. UsingVETs, technicians have access to a degree of interactivity that isn’t possiblewith physical units. With these new methods, technicians gain a precisefamiliarity through interactive engine cutaways, seeing how the components andgearing work together.

This new technology allows students to conduct practical maintenance proceduressuch as part replacement, X-ray and move functionality, further enablingstudents to view dynamic cross-sections of nearly every engine part.

In another benefit, virtual engines enable maintenance tasks to besimulated in guided, step-by-step processes allowing students to virtuallydisassemble and perform various line replacement unit changes in a simulation.Integrating the virtual experience into standard maintenance courses givestechnicians the full picture of how each component works, complementingpractical hands-on and classroom instruction.

A New Way to Test and Inspect

Technicians have a great advantage using the VET technology withinspections. The VET allows techs and trainers to simulate an engine inspectionduring borescope training. They can be virtually altered to representirregularities found in a turbine engine, with a variety of scenarios ordegrees of damage possible to simulate. Technicians are challenged to assessthe damage and are evaluated based on engine health and dispatchability. Withtraditional physical engine trainers, the possibilities are limited andcost-prohibitive to reproduce.

It is a similar concept as in FlightSafety’s simulator training forpilots where potentially hazardous scenarios can be safely simulated for pilotsto hone their skills. With the virtual borescope training, technicians get moreexamples of many more types of damage, or the signs of wear and tear, than theycould on a physical component. Most physical models are present only as ideal-stateengines, depriving technicians of what they’re likely to experience inreal-world scenarios on the line.

The VET technology is so advanced that some regulatory agencies areallowing it as an assessment method for up to 50 percent of practical enginetraining. This tool allows students to meet requirements more quickly andefficiently, thereby enhancing the value of the training provided.

Like many FlightSafety programs, it is available in a variety ofLearning Centers and locations, including the United States, Australia, Brazil,Canada, China, France, and India. The rollout currently covers courses on the PT6, PT6A, PT6E, PT6C, PT6T, PW206, PW300 and PW800 series.

FlightSafetyhas been preparing technicians for years to meet the challenges of thecorporate aviation industry. This cutting-edge program is another instance ofFlightSafety empowering these skilled workers with the practical and strategicknowledge needed to further career development and achieve their professionalgoals.