Several types non-destructive testing are used to diagnose the safe condition of stay cables in bridges9, such as ultrasonic testing, the magnetic flux leakage detection technique10, or X-rays. Although effective, these techniques are more suitable for the assessment of out-of-service stays.

On the one hand, various devices have been developed for the direct measurement of strain in bridge cables, such as load cells9,10,11,12,13,14,15, optical fibre Bragg grating sensors16, or elastomagnetic strain sensors17,18.

These sensors are able, thanks to their specific technologies, to accurately determine the stress experienced by the cable, and, when connected to a Structural Monitoring System (SMS), it is possible to create a long-term historical record of cable stresses as well as to access this data in real time from any remote location.

On the other hand, the most common indirect methodology for the rapid assessment of bridge cable stresses is the vibrating wire technique. This method is based on the relationship between cable stress and its vibration frequency, which can be correctly identified from the recording of accelerations during free vibration of suspension cables19,20,21,22,23,24. The application of this method requires the use of spectral decomposition techniques that allow for a real-time determination of the stresses in the suspension cables in bridges by identifying the vibration frequencies during a free vibration regime25,26,27,28,29,30,31.

There are many types of sensors for each of the measurement techniques32,33,34,35.

Electronical and micro electro-mechanical system sensors (MEMS)

Electronical sensors transform the measurement (parameter to be measured) into a change in voltage, current, resistance, capacitance or inductance. Electrical sensors come in many varieties and are often very simple to interface to any datalogger system. Examples include potentiometer displacement sensors, resistive strain-gauges, load cells, MEMS36 tiltmeters and piezoelectric sensors. Electrical sensors are often relatively inexpensive but can be subject to drift and can be affected or damaged by electromagnetic disturbances such as power lines.

Vibrating wire

Vibrating Wire (VW) sensors37 transform the measuring into a chance in the vibration frequency of a wire. In the case of VW strain sensor, a change in strain results in a change in the tension of a steel wire, while in the case of VW piezometers the deformation of a membrane due to a change in water pressure also induces a change in the tension of the sensor wire. Once the wire is excited by an electromagnet, it is possible to accurately measure its vibration frequency. The frequency measurements are very accurate and stable, which is why these sensors have become a standard for accurate long-term measurement in geotechnical and structural monitoring.

Optical fibre sensors

From many points of view, optical fibre sensors38 are the ideal transducers for structural health monitoring. These sensors transform the quantities to be measured into a change in the propagation characteristic of the light travelling through the optical fibre. Being durable, stable and insensitive to external disturbances, they are particularly useful for long-term health assessment of civil structures and geostructures. Many different fibre optic sensor technologies exist, including Fibre Bragg Gratings, SOFO Interferometer, Fabry Perot Interferometer and distributes Brillouin and Raman sensors, and offer a wide range of performances and suitability for different applications.

In the early 1990s, fibre optic sensors made a major entry into the sensor industry and now have an established presence in the structural sensing industry39.

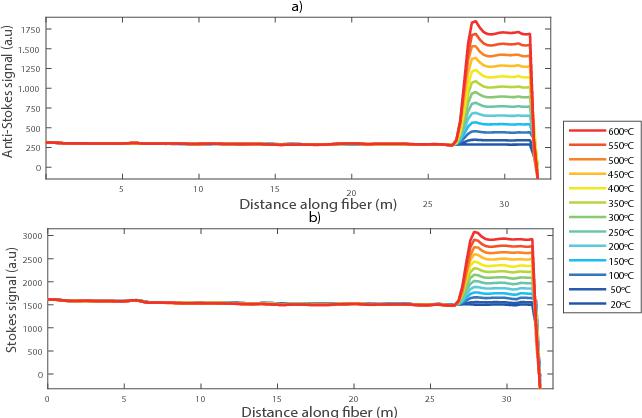

Distributed sensing

Distributed fibre sensors40,41 represent a paradigm shift in terms of monitoring and sensing. Distributed sensors are able to detect at any point along a single standard telecommunication fibre optics, which allows discriminating different positions of the measured parameter along the fibre, transferring strain and temperature from the structure to the fibre.

Distributed sensors are specially recommended42 for detecting and discriminating events at any point within a structure.

Optical/radar/laser

These techniques are particularly useful for monitoring the global movements of structures43. They include traditional geodesy methods, total stations with or without target prisms installed on the structure, laser distance meters and laser profilometers as well as terrestrial radars (including synthetic aperture radar). Those techniques can be sued for example, to measure the deformation of a bridge, the movement of a tower, the progression of a landslide or the deflection of a dam.

Image based techniques

Olaszek44 developed a method that incorporated the photogrammetric principle with computer vision technique to investigate slow dynamic characteristics of bridges.

Patsias and Staszewski45 and Yoshida et al.46 started the use of videogrammetric techniques to measure mode shapes of a beam and to capture the 3D dynamic behavior of different structures. Chung et al.47 used digital image techniques for identifying nonlinear characteristics in more complex structural systems. Chang and Ji48 developed a two-camera videogrammetric technique for measuring a 3D structural vibration response at laboratory level. In49, Ji and Chang proposed a novel nontarget technique based on image analysis using one digital camera for cable vibration measurement but, again, it is a proof-of-concept.

These techniques, although promising and most of them verified at laboratory level or under controlled conditions, do not seem to provide complete dynamic information, only a part of the free vibration. Therefore, application during construction must await a more advanced level of development.